← Back to Build Instructions Overview Page

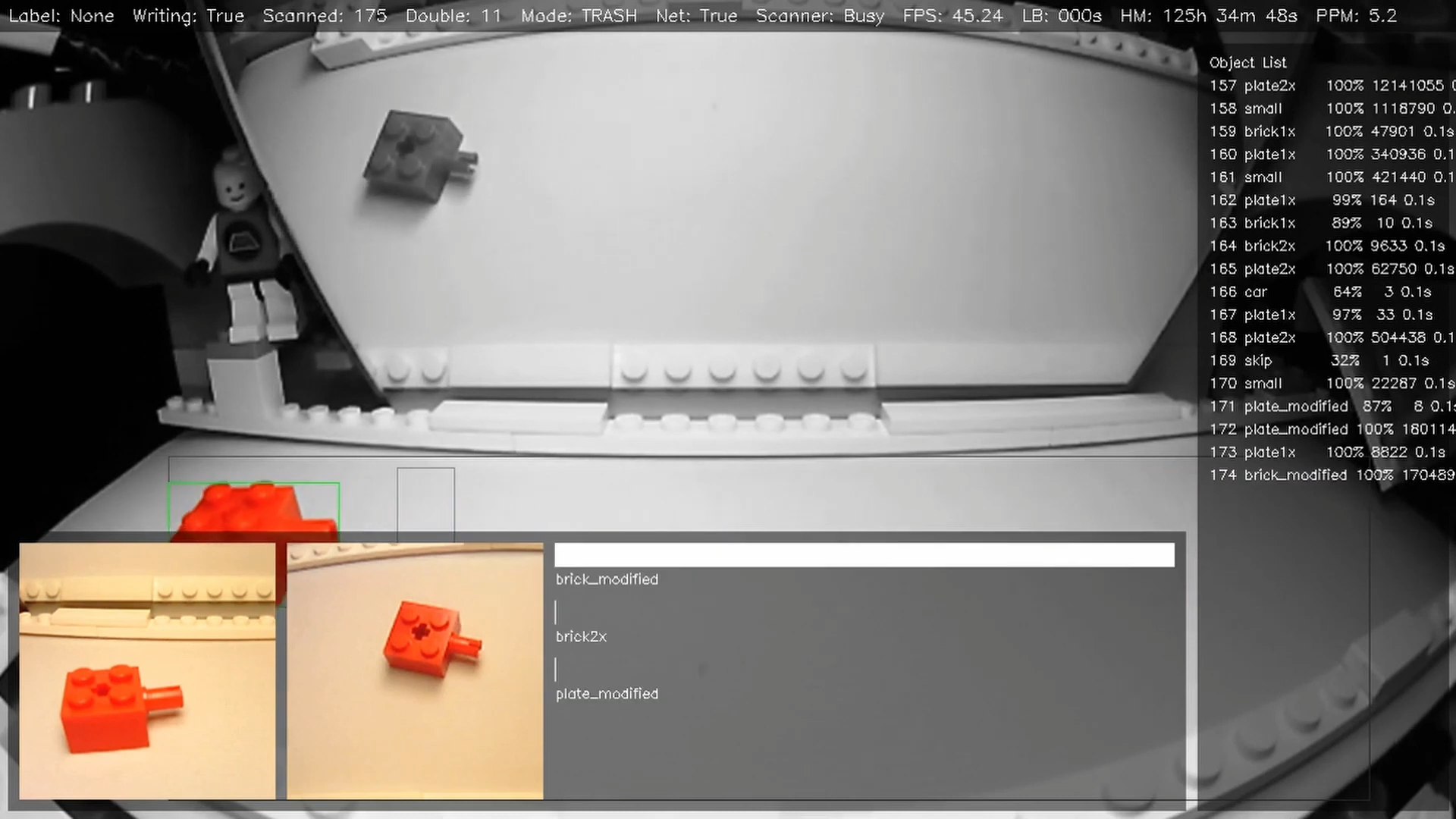

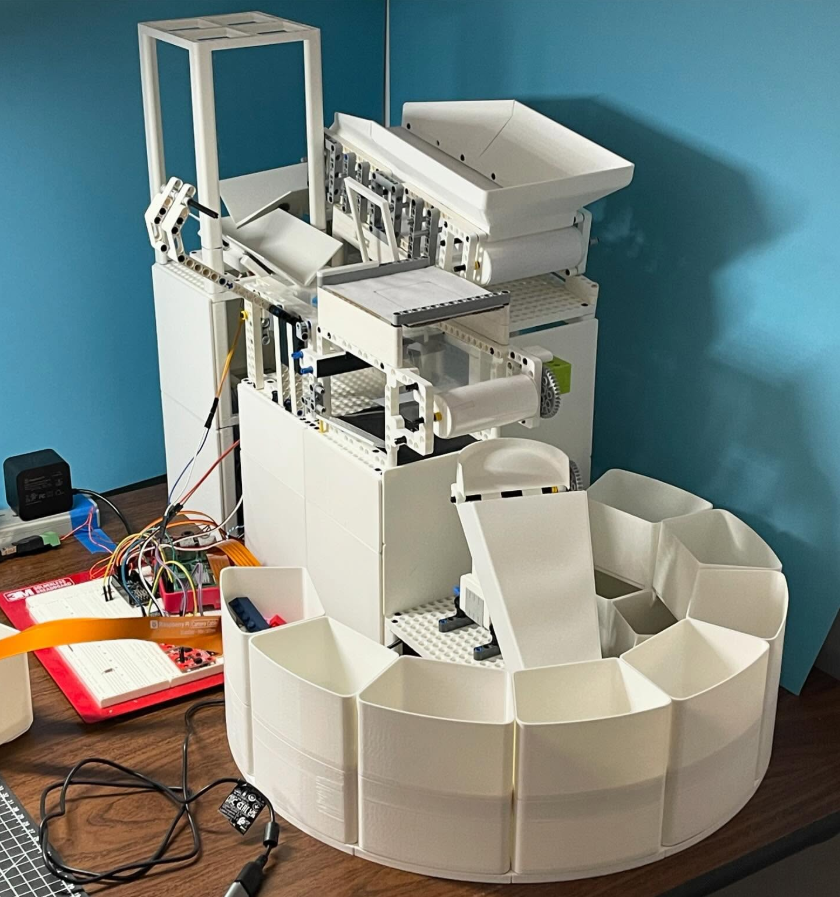

The task of part separation is to take the entangled stream of bricks and separate it into individual parts which can be passed on to the scanner strictly one by one at a time. Separation is especially challenging with LEGOs, since the parts have a huge variety in size (e.g. 1x1 plates stuck inside a window) and also friction (e.g. bricks vs. rubber wheels). When building a LEGO Sorting Machine this is one of the key components to get right since large parts of the efficiency of the overall machine depend on it.

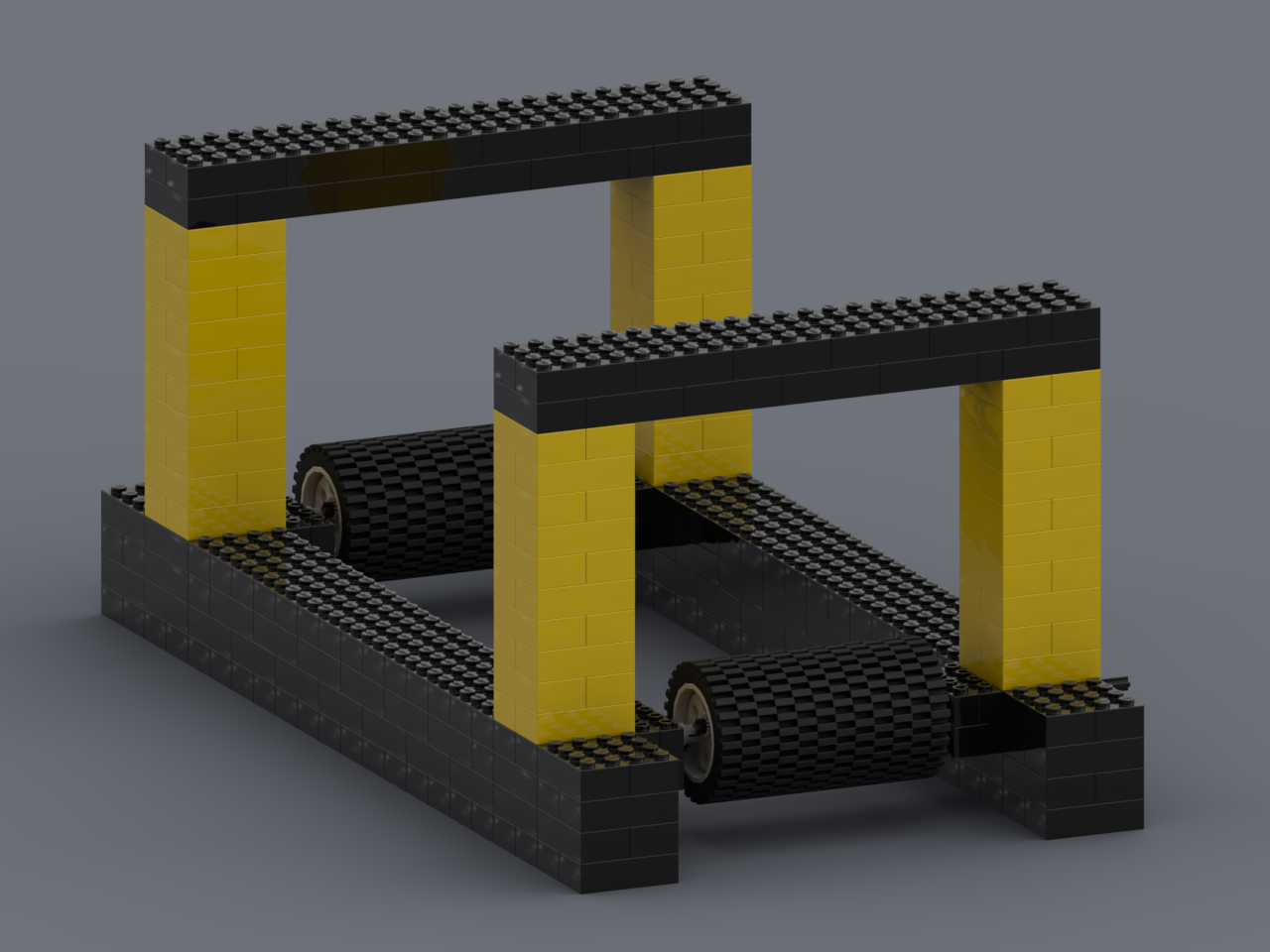

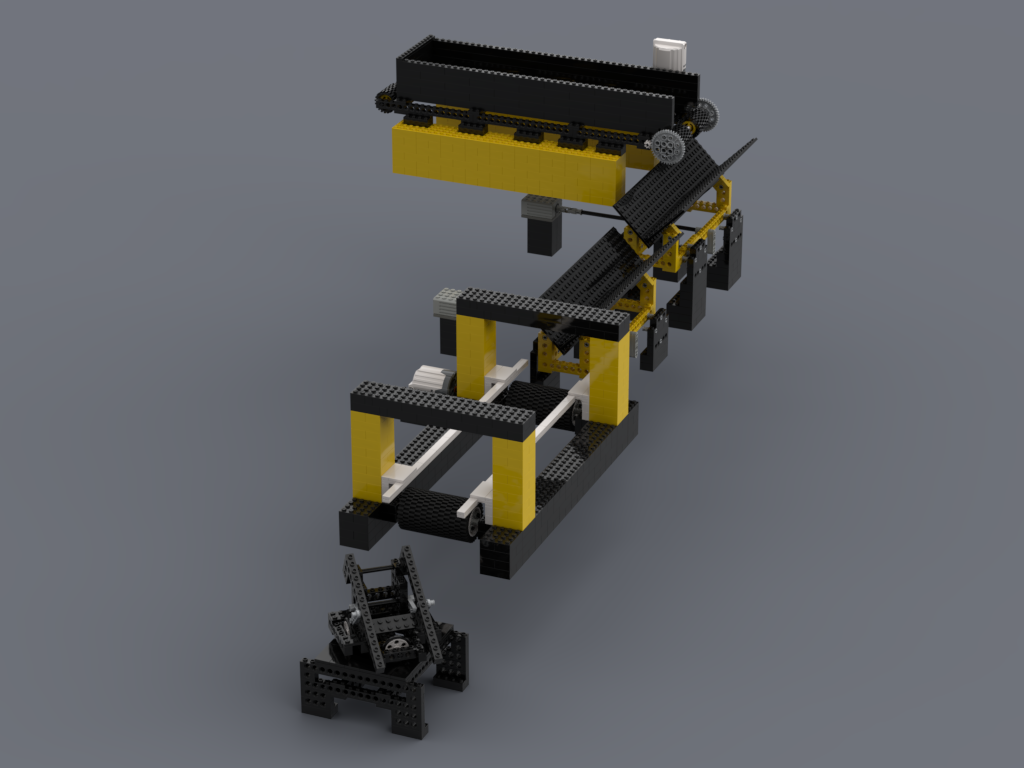

There is a big variety of potential designs and many earlier machines implemented this component. The approach I chose is a pair of v-channel vibration feeders and this article provides building instructions as well as bricklink studio CAD files.

The Build

Additional Information

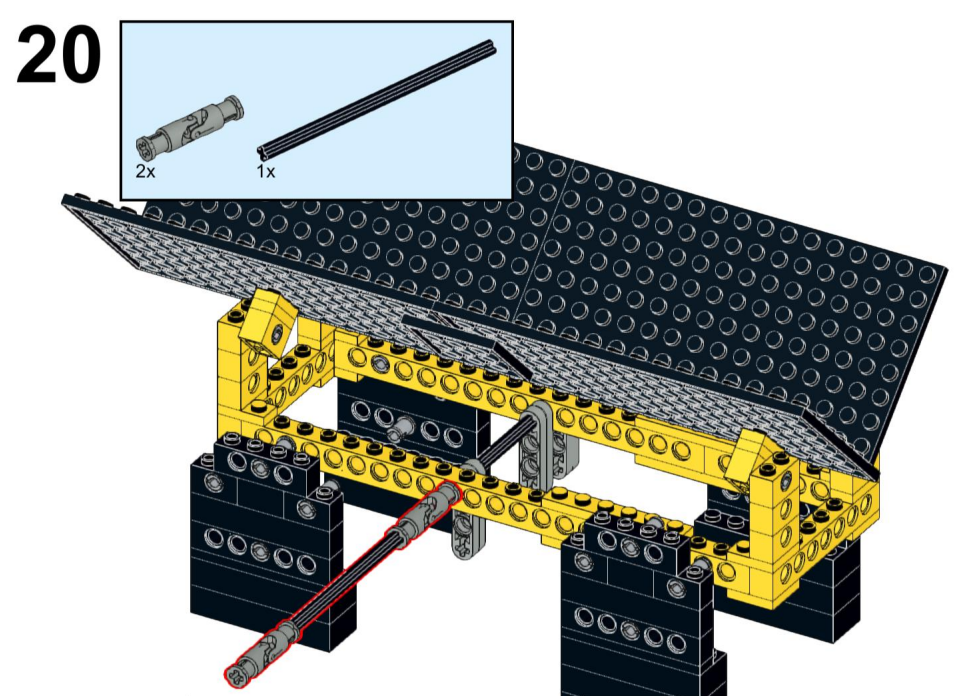

Why 2 channels in series - Having multiple vibration channels behind each other has 2 key advantages. The first is that channel 2 is pulsed twice as often as channel 1. The parts thus move at higher speeds. Having two different speeds “pulls” the parts apart from each other longitudinally. The second advantage is the vertical step between both channels. The small fall gives another chance to separate strongly entangled parts e.g. two window elements.

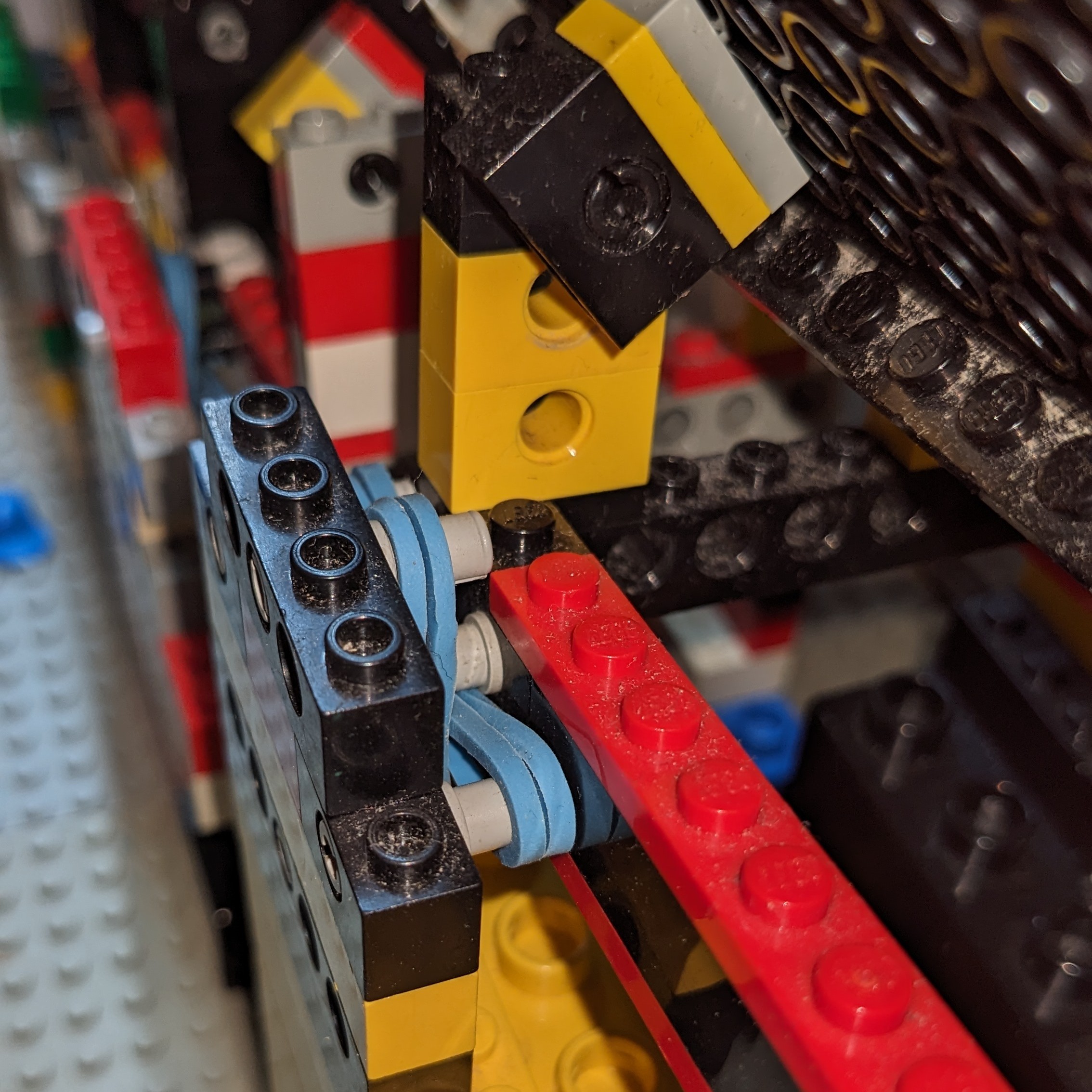

Rubber Bands - The v-channel is suspended from 2 rubber bands at each corner. 1 band to carry the vertical load of the v-channel and 1 band to center the longitudinal position. The offset weight of the vibration motor moves the v-channel in the freedom the rubber bands provide. Only the lateral position is fully constrained. I will post a photo as soon as possible.

Elastic mount of the v-channel using rubber bands. The mounting is flexible in vertical and longitudinal direction but constrained laterally (sry for the dust - the machine is located in a former wood shop 😊)

Elastic mount of the v-channel using rubber bands. The mounting is flexible in vertical and longitudinal direction but constrained laterally (sry for the dust - the machine is located in a former wood shop 😊)

Tuning - This v-channel has several adjustable parameters. 1) the inclination of the channel 2) the motor speed 3) the mass of the offset-weight. Alls these parameters need to be tuned to your specific machine. Over very long periods of time I also noticed the optimal parameters to slightly change. I chose the old 9V motors for their high RPMs but high speed is not always best. I tuned their speed via the motor driver to hit the resonance frequency of my v-channel. This way the motion is strong enough to disentangle the lego parts. Also the inclination needs to be calibrated to a sweet spot. It needs to be steep enough to still transport the parts forward. It needs to be shallow enough so that entangled pieces do not pass through the v-channel too quickly.

Surface - To reduce surface friction of the plates I added paper sticky tape and it works very well. Adding tiles on top of the plates would increase the mass of the v-channel and thus require a bigger vibration motor. Using large tiles instead of the plates could be another solution, they then require a different technique to be joined at the bottom.

Est. Cost - The pure material cost of a v-channel is approx €20 according to the part list on BrickLink.